High vacuum baffle valve recommendation

The high vacuum flapper valve is in the vacuum state, when the temperature of water or steam is higher than the boiling point, they enter the pump cavity as a gas. ②The spool valve pump itself is a heating source, and the liquid ring pump separates the spool valve pump. The separator provides a low pressure, so the water or other steam discharged to the separator is also in a vacuum state, and the temperature is high enough to keep them in a gas state, any tiny droplets will be evaporated in the separator, ③ discharged to The water or other steam in the liquid ring pump is due to the low temperature in the liquid ring pump.

When the temperature of the high vacuum flapper valve body cavity of the vacuum valve body cavity rises and abnormal pressure rises, it does not need to go through the safety valve, but the valve seat function can automatically release the pressure, which ensures the safety of the valve when transporting liquid media. It is very important. Among the basic conditions of vacuum valves, the essential positioning goals of the valve are consistent with the needs of life. It is also a reliable choice that allows the practical valve function to achieve better application possibilities, especially the production of brand-style valves. Selection is the key to the function positioning and quality assurance of the valve.

Beipiao Vacuum Equipment Co., Ltd. has a technical team with rich practical experience and specializing in the research and development of vacuum equipment. Over the years, through the continuous exploration and innovation of several generations of Beipiao people, the company can design and manufacture high vacuum oil diffusion pumps. , Oil diffusion jet vacuum pumps, various series of vacuum valves and vacuum units, etc., including more than 20 series of vacuum application equipment, more than 100 varieties of products.

High-vacuum valve vacuum systems are widely used in various processes. There are many types. According to the state of the vacuum system pumping process, it can be divided into two basic types, open vacuum system and closed vacuum system, the so-called open In a vacuum system, if there is gas flowing in the system, the pressure varies from place to place, and there will be a pressure difference between each section of the vacuum system. The first-stage vacuum pump will be pumped to the atmosphere, while the closed vacuum system is pumping. The equipment and the pumped container are closed together.

Vacuum valve vacuum valve packing gland should not be over-tightened. It is advisable that the valve stem can rotate sensitively. Pressing too tightly will increase the frictional force of the valve stem and increase the operating torque. When the valve is operated, it should not be arbitrarily under normal circumstances. Replace or add packing under pressure, otherwise, it will cause the risk of medium leakage. The electromagnetic vacuum belt inflation valve and electromagnetic vacuum pressure difference valve are vacuum valves specially used to prevent the mechanical vacuum pump from returning oil. They are installed at the air inlet of the mechanical vacuum pump. Turn on and off synchronously with the pump.

Since its transformation in 2000, Beipiao Vacuum Equipment Co., Ltd. has injected new vitality and vitality into the enterprise. It has successively developed large-caliber and special-shaped electric and pneumatic high-vacuum flapper valves. It has also developed rapid development for national defense and scientific research departments. Closed high-temperature water-cooled large flapper valve has become a domestic manufacturer of oversized valves.

High vacuum baffle valve recommendation

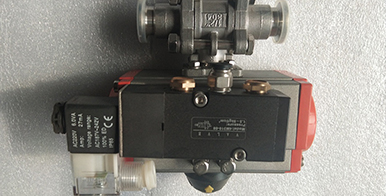

High vacuum flapper valve The vacuum valve is driven by electromagnetic force to directly drive the valve plate to open or close the valve. It is suitable for cutting off or conducting air flow in vacuum system. The applicable medium is pure air and non-corrosive gas. With feedback signal. The vacuum butterfly valve changes the direction of the gas path through the electromagnetic reversing valve, and controls the cylinder to drive the butterfly valve to open and close. Used to connect or cut off the air flow in the vacuum pipeline. The applicable medium is pure air and non-corrosive gas. Optional feedback signal device and electric valve.

Precautions for the use of the valve vacuum valve 1. When the vacuum valve is stored and transported, the pressure of the sealing parts will be reduced, which will cause the loosening of the screws and nuts. In order to avoid the leakage caused by this, the vacuum valve must be used before use Tighten each screw. 2. When the vacuum valve uses high-temperature fluids such as steam, the tightened screws will become loose due to the reduced pressure on the sealing parts, resulting in leakage. Therefore, the loose screws should be tightened immediately.

The products and services of Beipiao Vacuum Equipment Co., Ltd. are spread all over the country and have been well received by users. Our tenet is: "Customer needs are the goal we are constantly pursuing." Honesty, dedication, pioneering, and innovation are the company's spirit. We will provide high-tech products and various forms of services for domestic and foreign users. We look forward to sincere cooperation with colleagues from all walks of life. , Go hand in hand, create brilliant together!