Which high vacuum flapper valve is reliable

The sealing performance test of the high vacuum flapper valve The opening and closing force and opening and closing torque of the vacuum flap valve refer to the force or torque that must be applied to open or close the valve. When closing the valve, it is necessary to make the sealing surface of the opening and closing part and the seat A certain seal specific pressure is formed between them, and the friction between the valve stem and the packing, between the thread of the valve stem and the nut, the end support of the valve stem and other frictional forces must be overcome, so a certain closing force and Closing torque, the required opening and closing force and opening and closing torque of the valve change during the opening and closing process, and the maximum value is at the final moment of closing or the initial moment of opening.

The main contents of daily maintenance of high vacuum valve vacuum valve should include several items (1) the inner wall of the valve body, check its pressure resistance and corrosion resistance, (2) the valve seat, due to the infiltration of the medium, the threaded inner surface for fixing the valve seat is vulnerable If the valve seat becomes loose due to corrosion, pay attention when checking. For vacuum valves, check whether the sealing surface of the valve seat is damaged in high-pressure situations. Check carefully whether all parts of the valve core are corroded and worn, especially in high pressure conditions. The lower spool wears more serious, and the vacuum valve should be paid attention to.

Beipiao Vacuum Equipment Co., Ltd. specializes in the research and development, design and production of vacuum valves, vacuum chambers, molecular pumps and molecular pump units with a highly skilled team, and continues to develop new products. Products are widely used in aerospace, technology, coating, solar energy, vacuum furnace industry, energy, metallurgy, chemical industry and many other industries.

After the test of the high vacuum flapper valve, the joint and the sealing part of the valve body are deformed at the same time, and the sealing surface of the valve body will produce indentation, which is not conducive to multiple sealing. During the process of tightening the outer nut, if the joint and the outer nut rotate together, it will be damaged On the sealing surface of the valve body of the product, foreign matter of the vacuum valve is embedded between the diaphragm and the valve seat, compressing or abrading the diaphragm; prevention and elimination method: do not force to close during operation, and open and close repeatedly up and down several times. After the foreign matter is washed away, the valve is officially closed. ; Replace in time when the diaphragm is damaged.

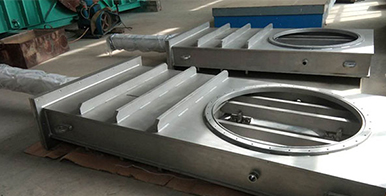

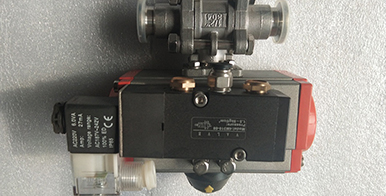

High-vacuum flapper valve. The flapper valve is used in the corner and three-way places in the vacuum pipeline. The flapper valve is used in the occasions where the vacuum degree is high or the pipeline size is high. The diaphragm valve and the ball valve are straight-through and can be used in the normal Where pressure and vacuum coexist, the butterfly valve is in straight-through mode. The three driving modes of hand, air and electric are determined by the user. The valve stored for a long time should be checked regularly to clean up the dirt and apply anti-rust oil on the processing surface. , Should be checked regularly, the first check item: the wear condition of the sealing surface.

The main service groups of Beipiao Vacuum Equipment Co., Ltd.: colleges and universities; research institutes; customers with high vacuum and ultra-high vacuum requirements. The company takes scientific development, forge ahead, the pursuit of excellence, and casting fine products as the development concept. "Customer first, service first" is the business policy.

Which high vacuum flapper valve is reliable

The high vacuum flapper valve is in the vacuum state, when the temperature of water or steam is higher than the boiling point, they enter the pump cavity as a gas. ②The spool valve pump itself is a heating source, and the liquid ring pump separates the spool valve pump. The separator provides a low pressure, so the water or other steam discharged to the separator is also in a vacuum state, and the temperature is high enough to keep them in a gas state, any tiny droplets will be evaporated in the separator, ③ discharged to The water or other steam in the liquid ring pump is due to the low temperature in the liquid ring pump.

High vacuum baffle valve gate valve should not be inverted, otherwise, the medium will stay in the valve cavity for a long time, which will easily corrode the valve stem. Rising stem gate valve should not be installed underneath to prevent the wheel rod from rusting. When installing or replacing heavier gates , Lifting locks cannot be tied to the handwheel or valve stem, but should be tied to the valve body to avoid damage to the handwheel or valve stem and other parts. The check valve has two types: lift check valve and swing check valve. It can only be installed horizontally. The swing check valve must be installed horizontally with its shaft pin. The swing check valve can be used on horizontal and vertical pipelines.

The main products of Beipiao Vacuum Equipment Co., Ltd. vacuum valves include: ultra-high vacuum flapper valve, high vacuum butterfly valve, high vacuum baffle valve, ultra-high vacuum all-metal angle valve, ultra-high vacuum all-metal fine-tuning valve, etc. The valve diameter ranges from 10mm to 1200mm, the applicable temperature range is -80℃~~+400℃, and the applicable pressure range is 105~~10-8pa.

The main products of the vacuum chamber are: arc structure, round structure, square structure, various vacuum pipes can be processed and manufactured according to the drawings, and the cavity size ranges from 0.1 to 16m.