Where to find the valve

The professional maintenance of the vacuum valve before and after the welding is put into production, which plays a vital role in the production and operation of the valve. Correct, orderly and useful maintenance will maintain the valve, make the valve function and extend Valve service life, valve maintenance operations seem to be simple, but it is not. There are often overlooked aspects in the operation. When the vacuum valve is greased, the problem of grease injection is often ignored. After grease injection, the operator chooses the valve and grease injection combined method After that, grease injection is performed.

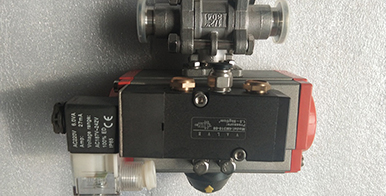

Vacuum valve The vacuum valve uses an electric device to drive the valve stem and ball core to perform opening and closing actions to connect or cut off the medium flow in the vacuum (pressure) system pipeline. It is used in vacuum, dairy products, wine industry, biological engineering, In the fields of food, pharmacy, beverage, cosmetics and chemical industry, in order to ensure the elasticity of the packing, the vacuum valve is generally subject to static pressure test. After the valve is installed in the pipeline, due to temperature and other factors, it may happen For extravasation, tighten the nuts on both sides of the packing gland in time.

Beipiao Vacuum Equipment Co., Ltd. specializes in the research and development, design and production of vacuum valves, vacuum chambers, molecular pumps and molecular pump units with a highly skilled team, and continues to develop new products. Products are widely used in aerospace, technology, coating, solar energy, vacuum furnace industry, energy, metallurgy, chemical industry and many other industries.

High-vacuum flapper valves, gate valves and globe valves, etc., when closed or opened to the end (ie bottom dead center or top dead center), they must be reversed 1/4 to 1/2 turn to make the threads more tightly closed. Check when it is advantageous to operate to prevent over-tightening and damaging the valve. Large-diameter butterfly valves, gate valves and stop valves, and some are equipped with bypass valves. The function of the bypass valve is to balance the pressure difference between the inlet and outlet and reduce the opening torque. , The bypass valve should be turned on first, and then the large valve should be opened. Before opening the steam valve, it is necessary to preheat the pipeline to discharge the condensate.

Valve Vacuum valve refers to a vacuum system component used to change the direction of air flow, adjust the size of air flow, and cut off or connect the pipeline in the vacuum system. The closing part of the vacuum valve is sealed with a rubber seal or a metal seal. The gate of the vacuum valve moves linearly along with the valve stem. It is called a lifting stem gate valve (also called a rising stem gate valve). There is usually a trapezoidal thread on the lifting stem, which rotates through the nut on the top of the valve and the guide groove on the valve body. The motion becomes linear motion, that is, the operating torque is changed to operating thrust.

The main service groups of Beipiao Vacuum Equipment Co., Ltd.: colleges and universities; research institutes; customers with high vacuum and ultra-high vacuum requirements. The company takes scientific development, forge ahead, the pursuit of excellence, and casting fine products as the development concept. "Customer first, service first" is the business policy.

Where to find the valve

Vacuum valve When the mechanical pump stops working, the valve can be opened immediately to let the inlet of the mechanical pump enter the atmosphere to prevent the mechanical pump oil from flowing back into the pipeline. Therefore, the valve must be electrically interlocked with the mechanical pump, and the vacuum chamber must be electrically interlocked. Set up a vent valve for loading and unloading. The position of the valve should take into account that the gas has a greater impulse when deflating to prevent damage to the weak components in the vacuum chamber due to excessive impulse. The size of the vent valve is The volume of the vacuum chamber is related, and the deflation time should not be too long, which will affect the work.

When the temperature of the medium in the valve body cavity rises and abnormal pressure rises, it does not need to go through the safety valve, but the valve seat function can automatically release the pressure. This is very important to ensure the safety of the valve when transporting liquid media. Among the basic conditions of the valve, the essential positioning goal of the valve is consistent with the needs of life, and it is also a reliable choice that allows the practical valve function to achieve better application possibilities, especially the production of brand-style valves, which pays attention to the choice of materials. Its functional positioning and quality assurance are both key.

The main products of Beipiao Vacuum Equipment Co., Ltd. vacuum valves include: ultra-high vacuum flapper valve, high vacuum butterfly valve, high vacuum baffle valve, ultra-high vacuum all-metal angle valve, ultra-high vacuum all-metal fine-tuning valve, etc. The valve diameter ranges from 10mm to 1200mm, the applicable temperature range is -80℃~~+400℃, and the applicable pressure range is 105~~10-8pa.

The main products of the vacuum chamber are: arc structure, round structure, square structure, various vacuum pipes can be processed and manufactured according to the drawings, and the cavity size ranges from 0.1 to 16m.