Valve Service Hotline

If the high vacuum valve is classified according to the working pressure of the actual starting system, there can be rough vacuum system, low vacuum system, high vacuum system, ultra-high vacuum system and extremely high vacuum system. According to the cleanliness of the vacuum system, there will be oil Vacuum systems and oil-free vacuum systems. Due to people’s habits, the above-mentioned different categories are often integrated in practical applications, such as "large dynamic metal high vacuum systems", "oil-free ultra-high vacuum systems", etc. Therefore, the above The classification method is not strictly constant.

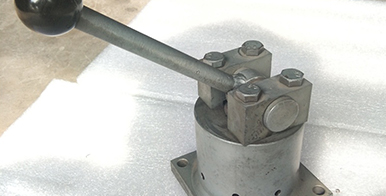

High vacuum baffle valve vacuum valve nominal diameter: (nominaldiameter), also known as mean outside diameter (meanoutsidediameter), represents the symbol DN, which is the general diameter of various pipes and pipeline accessories. The inner diameter, although its value is close to or equal to the inner diameter of the pipe, in order to unify the connecting dimensions of the pipe and fittings, the nominal diameter (also called the nominal diameter and the nominal diameter) is adopted.

Beipiao Vacuum Equipment Co., Ltd. has a technical team with rich practical experience and specializing in the research and development of vacuum equipment. Over the years, through the continuous exploration and innovation of several generations of Beipiao people, the company can design and manufacture high vacuum oil diffusion pumps. , Oil diffusion jet vacuum pumps, various series of vacuum valves and vacuum units, etc., including more than 20 series of vacuum application equipment, more than 100 varieties of products.

If the vacuum valve is divided according to the working pressure of the actual starting system, there can be a rough vacuum system, a low vacuum system, a high vacuum system, an ultra-high vacuum system and a very high vacuum system. According to the cleanliness of the vacuum system, there will be oil vacuum System, oil-free vacuum system, due to people’s habits, the above-mentioned different categories are often integrated in practical applications, such as "large dynamic metal high vacuum system", "oil-free ultra-high vacuum system", etc. Therefore, the above The classification method is not strictly constant.

The main contents of the daily maintenance of the high vacuum flapper valve vacuum valve should have several items (1) the inner wall of the valve body, check its pressure resistance and corrosion resistance, (2) the valve seat, due to the penetration of the medium, the threaded inner surface of the valve seat It is easy to be corroded and make the valve seat loose. Pay attention when checking. For vacuum valves, check whether the sealing surface of the valve seat is damaged in high pressure situations. Check carefully whether all parts of the valve core are corroded and worn, especially under high pressure. The valve core is more severely worn under poor conditions, and the vacuum valve should be paid attention to.

Since its transformation in 2000, Beipiao Vacuum Equipment Co., Ltd. has injected new vitality and vitality into the enterprise. It has successively developed large-caliber and special-shaped electric and pneumatic high-vacuum flapper valves. It has also developed rapid development for national defense and scientific research departments. Closed high-temperature water-cooled large flapper valve has become a domestic manufacturer of oversized valves.

Valve Service Hotline

Vacuum valve vacuum valve packing gland should not be over-tightened. It is advisable that the valve stem can rotate sensitively. If it is pressed too tightly, it will increase the friction of the valve stem and increase the operating torque. When the valve is operated, it should not be arbitrarily under normal circumstances. Replace or add packing under pressure, otherwise, it will cause the risk of medium leakage. When the diameter of the vacuum valve is different from that of the process pipeline, a reducer should be used for connection. When installing a small-diameter control valve, it can be connected by thread, and the flow direction of the valve body Should be consistent with the fluid direction.

Before leaving the factory, the opening pressure of the high vacuum valve safety valve should be adjusted to the set value required by the user one by one. If the user proposes the spring working pressure level, it should generally be adjusted according to the lower limit of the pressure level. The user is installing the safety valve Before going to the protected equipment or before installing, it must be re-adjusted at the installation site to ensure that the set pressure value of the safety valve meets the requirements. In order to ensure the accuracy of the pressure value in the opening of the vacuum valve, the media conditions during adjustment should be adjusted, such as medium The type and temperature are as close to the actual operating conditions as possible.

The products and services of Beipiao Vacuum Equipment Co., Ltd. are spread all over the country and have been well received by users. Our tenet is: "Customer needs are the goal we are constantly pursuing." Honesty, dedication, pioneering, and innovation are the company's spirit. We will provide high-tech products and various forms of services for domestic and foreign users. We look forward to sincere cooperation with colleagues from all walks of life. , Go hand in hand, create brilliant together!