Where is the high vacuum valve company

Definition and classification of vacuum valves: Vacuum valves are used in fluid systems. The devices used by vacuum valves to control the direction, pressure, and flow of fluid are to make the medium (liquid, gas, powder) flow or stop in piping and equipment. A device that can control its flow. The vacuum valve is in a fluid system. The device used to control the direction, pressure and flow of the fluid is the vacuum valve to make the piping and the medium (liquid, gas, powder) flow or stop and control it Its flow device.

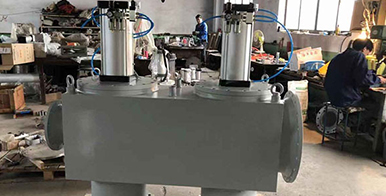

High-vacuum baffle valve, as an important component in the vacuum system to connect or cut off the pipeline and adjust the gas volume, it will often be encountered in the construction of the vacuum system. In today’s small class, we will popularize the vacuum valve model for everyone Quickly identify the method. Before you understand the vacuum valve model, you can review the general classification of vacuum valves in "Screw Vacuum Pump Manufacturers Counting the Components of Vacuum System". According to so many types of vacuum valves, JB/T7673-95 stipulates vacuum valves. Specific rules for model compilation.

Beipiao Vacuum Equipment Co., Ltd. (formerly Beipiao Vacuum Valve Factory) was established in 1966 and is a designated enterprise of the former Ministry of Machinery and Electronics. The total area of the plant is over 50 acres. The main plant is located in the Taiji Management Zone of Beipiao City. The new plant is located in the Light Textile Industrial Park of the Economic Development Zone of Beipiao City. The total investment exceeds 100 million yuan. There are 62 employees, including 12 engineers and technicians. The company has more than 100 sets of various processing and manufacturing equipment and nearly 20 patented technologies. Over the years, it has been innovating and making progress. It has grown into a professional vacuum acquisition, A high-tech enterprise engaged in vacuum application technology development and equipment manufacturing.

The professional maintenance of high-vacuum flapper valves before and after they are put into production before welding plays a vital role in the production and operation of the valves. Correct, orderly and useful maintenance will maintain the valves and make the valves function normally. Function and extend the service life of the valve. The maintenance of the valve seems simple, but it is not. There are often overlooked aspects in the operation. When the vacuum valve is greased, the problem of grease injection is often ignored. After grease injection, the operator selects the valve and injection After the fat joint method, perform fat injection.

High vacuum flapper valve Vacuum valve refers to the vacuum system component used to change the direction of air flow, adjust the size of the air flow, and cut off or connect the pipeline in the vacuum system. The closing part of the vacuum valve is made of rubber seal or metal seal. For sealing, the vacuum valve airtight water test work should be checked and accepted in strict accordance with the standard. Underground buried, suspended ceiling, Prince and other concealed sewage, rain, condensed water pipes, etc., ensure that there is no leakage and no leakage. The vacuum valve should not be used before the pipeline system is flushed. Seriously, the flow and speed do not meet the requirements of pipeline flushing.

The company is located in Beipiao City, Liaoning Province, in the west of Liaoning Province, with the Bohai Sea in the south and Inner Mongolia in the north. It is an important part of the Bohai Rim Economic Circle. Beipiao City is rich in fossil resources and mineral resources. 44 types of mineral resources have been proven. Among them, gold mineral reserves are very rich, and the fossil industry is prosperous and diverse. It is known as "the world's first bird flying and the first flower blooming." The reputation of "place".

Where is the high vacuum valve company

The design of the valve vacuum system should ensure stable and reliable exhaust, easy installation, disassembly and maintenance, convenient operation, and interchangeability of connections between components. In order to achieve stable exhaust during work, stable performance of the main pump is required, and each valve is flexible and sealed. Reliable, the joints of the components in the system do not leak air, the vacuum chamber has good sealing performance, and the vacuum components are connected in standard sizes to ensure interchangeability. In the vacuum system design, in principle, each closed pipeline should have a size An adjustable size.

High-vacuum valve The vacuum valve uses an electric device to drive the valve stem and ball core to perform opening and closing actions to connect or cut off the medium flow in the vacuum (pressure) system pipeline. It is used in vacuum, dairy products, wine industry, and biological engineering. In the fields of food, pharmacy, beverage, cosmetics and chemical industry, in order to ensure the elasticity of the packing, the vacuum valve is generally subject to static pressure test. After the valve is installed in the pipeline, due to temperature and other factors, it may be When extravasation occurs, the nuts on both sides of the packing gland must be tightened in time.

The transportation in Beipiao City is very convenient. The Beijing-Shenzhen high-speed railway can directly connect to Beijing, Shenyang and other cities. National highways 101 and 305 and Changshen Expressway run through urban and rural areas. The central city is 45 kilometers away from Chaoyang Airport and 150 kilometers away from Jinzhou Port.