High vacuum valve contact information

High vacuum valve determines the geometric parameters of the selected valve: structural length, flange connection form and size, valve height dimension after opening and closing, connecting bolt hole size and number, overall valve outline size, etc., determine the connection with the valve The nominal diameter and connection method of the pipeline: flange, thread, welding, etc., determine the parameters of the valve: for automatic valves, first determine the allowable flow resistance, discharge capacity, back pressure, etc. according to different needs, and then determine the nominal diameter and The diameter of the seat hole.

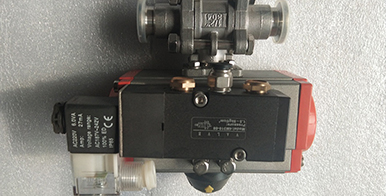

High-vacuum flapper valve tightness: as a shut-off valve for use in a vacuum environment, the tightness of a vacuum ball valve is a condition. Only by accurately achieving a reasonable seal can the air flow be managed to achieve an effective purpose, and the service standard, On the basis of professionalism, it is possible to improve the rational standard and the basic principles and characteristics of the service. Only when the basic conditions of sealing are truly met, can it be used in actual production and have a good function. It is also an actual production application. Important quality standards.

Beipiao Vacuum Equipment Co., Ltd. has a technical team with rich practical experience and specializing in the research and development of vacuum equipment. Over the years, through the continuous exploration and innovation of several generations of Beipiao people, the company can design and manufacture high vacuum oil diffusion pumps. , Oil diffusion jet vacuum pumps, various series of vacuum valves and vacuum units, etc., including more than 20 series of vacuum application equipment, more than 100 varieties of products.

When the vacuum valve is leak-tested on the weld of the cold trap liner after the assembly, the weld cannot be exposed to the outside after assembly, even if a leak is found, it cannot be repaired. Another example is that some large vessels are after the assembly. The volume is too large, so that the leak detection sensitivity is very low, and the vacuum valve cannot detect small leaks, thus failing to meet the requirements of leak detection. Considering similar situations, it should be done during the processing of parts and components. Welds are leak-tested, and the vacuum valve has broken bolts.

For high vacuum flapper valves, when this force is greater than the downward pressure of the diaphragm on the spool, the spool will move up and vibrate, especially under small signal conditions, because the pre-tightening force is small, which makes the spool more likely to occur. Trembling, the opening of the regulating valve is too small, so that the differential pressure before and after the regulating valve is too large, so that the flow rate at the saving port increases and the pressure decreases rapidly. If the pressure drops to the full vapor pressure of the liquid at that temperature, the vacuum The valve can vaporize the liquid to form a flash vaporization, generate bubbles, and when the bubbles burst, a strong pressure and shock wave are formed, and air hammer occurs.

Since its transformation in 2000, Beipiao Vacuum Equipment Co., Ltd. has injected new vitality and vitality into the enterprise. It has successively developed large-caliber and special-shaped electric and pneumatic high-vacuum flapper valves. It has also developed rapid development for national defense and scientific research departments. Closed high-temperature water-cooled large flapper valve has become a domestic manufacturer of oversized valves.

High vacuum valve contact information

The valve vacuum valve sleeve joint provides a reliable, leak-proof and sealed connection to avoid serious problems caused by vibration, thermal shock, improper installation and huge losses. The tube joint is always detectable. After the initial installation, The use of a gap detection gauge can ensure that the installation personnel or inspectors ensure that the ferrule joint is fully tightened. If the nut has been properly tightened, the detection gauge cannot be placed between the hexagonal end of the nut and the joint body. Sealant, etc. filler.

High-vacuum valve vacuum systems are widely used in various processes. There are many types. According to the state of the vacuum system pumping process, it can be divided into two basic types, open vacuum system and closed vacuum system, the so-called open In a vacuum system, if there is gas flowing in the system, the pressure varies from place to place, and there will be a pressure difference between each section of the vacuum system. The first-stage vacuum pump will be pumped to the atmosphere, while the closed vacuum system is pumping. The equipment and the pumped container are closed together.

The products and services of Beipiao Vacuum Equipment Co., Ltd. are spread all over the country and have been well received by users. Our tenet is: "Customer needs are the goal we are constantly pursuing." Honesty, dedication, pioneering, and innovation are the company's spirit. We will provide high-tech products and various forms of services for domestic and foreign users. We look forward to sincere cooperation with colleagues from all walks of life. , Go hand in hand, create brilliant together!