High vacuum flapper valve for sale

The routine maintenance method of the valve vacuum valve: 1. The valve stored for a long time should be checked regularly, cleaned up the dirt, and coated with anti-rust oil on the processing surface. 2. The valve should be stored in a dry and ventilated room. The two ends of the passage must be blocked. The vacuum valve 3. After installation, check regularly. The first check items: the wear condition of the sealing surface, the wear condition of the trapezoidal thread of the valve stem and the valve stem nut, whether the packing is out of date and invalid, if it is damaged, it should be replaced in time, and the valve should be repaired after installation. Sealing function experiment.

According to the shape of the wave, the vacuum corrugated pipe can be divided into two categories: spiral corrugated pipe and ring corrugated pipe: spiral corrugated pipe is a tube-shaped shell with corrugations arranged in a spiral shape. There is a spiral angle between the corrugation and the corrugation, all corrugations can be connected by a spiral line; the ring-shaped corrugated pipe is a tubular shell with the corrugation in a closed ring shape, and there is a ring between the corrugation and the corrugation. The ring-shaped corrugated tube can be divided into u-shaped, c-shaped, s-shaped, and v-shaped due to the same waveform.

Beipiao Vacuum Equipment Co., Ltd. specializes in the research and development, design and production of vacuum valves, vacuum chambers, molecular pumps and molecular pump units with a highly skilled team, and continues to develop new products. Products are widely used in aerospace, technology, coating, solar energy, vacuum furnace industry, energy, metallurgy, chemical industry and many other industries.

For vacuum valves, check and adjust the fully open or fully closed indication position of the gate valve and throttle valve with the mark. The rising stem gate valve and globe valve should also use their fully open and fully closed positions to prevent them from being fully opened. The dead center of the mouthpiece, when the valve is fully closed, the ruler and marks can be used to find that the closed part has fallen or resisted foreign objects for troubleshooting. The pipeline and equipment of the new installation have many internal dirt, welding ballast and other objects. Normally open the manual valve There are simple dirt on the sealing surface, use the micro-opening method to let the high-speed medium wash away these foreign objects.

According to the shape of the wave, the vacuum bellows can be divided into two categories: spiral bellows and ring bellows. The spiral bellows is a tubular shell with corrugations arranged in a spiral shape. There is a spiral angle between the corrugation and the corrugation, all corrugations can be connected by a spiral line; the ring-shaped corrugated pipe is a tubular shell with the corrugation in a closed ring shape, and there is a ring between the corrugation The ring-shaped corrugated tube can be divided into u-shaped, c-shaped, s-shaped, and v-shaped due to the original waveform.

The main service groups of Beipiao Vacuum Equipment Co., Ltd.: colleges and universities; research institutes; customers with high vacuum and ultra-high vacuum requirements. The company takes scientific development, forge ahead, the pursuit of excellence, and casting fine products as the development concept. "Customer first, service first" is the business policy.

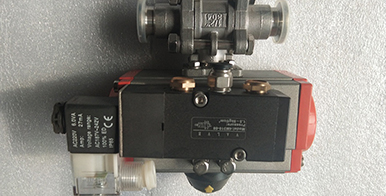

High vacuum flapper valve for sale

When the high vacuum flapper valve vacuum valve is used for leak detection on the welding seam of the cold trap inner tank after assembly, the welding seam cannot be exposed to the outside after assembly, even if a leak is found, it cannot be repaired, as in some large containers. After the final assembly, the volume is too large, so that the leak detection sensitivity is very low, and the vacuum valve cannot detect small leaks, thus failing to meet the requirements of leak detection. Considering similar situations, it should be used in the processing of parts and components. During the process, leak detection was performed on the weld, and the solution of broken bolts in the vacuum valve.

High-vacuum valve vacuum flange connection or flange joint refers to a foldable connection that is connected by flanges, gaskets and bolts as a set of combined sealing structure. Pipeline flange refers to the flange used for piping in pipeline installations. , Used on equipment refers to the inlet and outlet flanges of the equipment. It is reliable, can be opened in any direction, is easy to disassemble, and is easy to clean. The vacuum flange uses copper gaskets and flange knife edges to achieve vacuum sealing function. There are various types of cover, fixed and rotatable, and bolt holes are divided into so-called threaded holes and through holes.

The main products of Beipiao Vacuum Equipment Co., Ltd. vacuum valves include: ultra-high vacuum flapper valve, high vacuum butterfly valve, high vacuum baffle valve, ultra-high vacuum all-metal angle valve, ultra-high vacuum all-metal fine-tuning valve, etc. The valve diameter ranges from 10mm to 1200mm, the applicable temperature range is -80℃~~+400℃, and the applicable pressure range is 105~~10-8pa.

The main products of the vacuum chamber are: arc structure, round structure, square structure, various vacuum pipes can be processed and manufactured according to the drawings, and the cavity size ranges from 0.1 to 16m.