Where to buy valves

If the vacuum valve is used in the pipeline when the valve body leaks, we can take advantage of the fast curing speed of the adhesive to fill the pin with the adhesive in time to form a new solid sealing structure to achieve the purpose of preventing leakage. A method of using the special function of the adhesive to plug leaks under pressure. For pressure media and blisters with small leakage, you can first polish the vicinity of the leakage point to give a metallic luster, and then use a tapered pin to aim at the leakage point and drive in with appropriate strength .

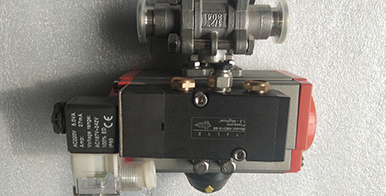

High vacuum flapper valve vacuum valve, determine the way to operate the valve: manual, electric, electromagnetic, pneumatic or hydraulic, electric linkage or electro-hydraulic linkage, etc., clarify the purpose of the vacuum valve in the equipment or device, and determine the working conditions of the valve: Applicable medium, working pressure, working temperature, etc., according to the medium, working pressure and working temperature conveyed by the pipeline to determine the material of the selected valve shell and internal parts: gray cast iron, malleable cast iron, ductile iron, carbon steel, alloy steel, Stainless acid-resistant steel, copper alloy, etc.

Beipiao Vacuum Equipment Co., Ltd. has a technical team with rich practical experience and specializing in the research and development of vacuum equipment. Over the years, through the continuous exploration and innovation of several generations of Beipiao people, the company can design and manufacture high vacuum oil diffusion pumps. , Oil diffusion jet vacuum pumps, various series of vacuum valves and vacuum units, etc., including more than 20 series of vacuum application equipment, more than 100 varieties of products.

High-vacuum flapper valve The vacuum valve has a high functional accuracy, and the realization of effective adjustment of the airflow direction and size of the vacuum environment is the standard that its function needs to meet. The vacuum ball valve is used as a ball valve product under vacuum conditions. , Not only does the basic function of cut-off have standard accuracy, but also while realizing effective cut-off function guarantee, it can also serve the needs of vacuum environment management. It is necessary to ensure that there is a good management function. Practical application of vacuum valve products.

Installation and application of high vacuum valve vacuum valve 1. The vacuum valve should be equipped with a filter to prevent impurities in the medium from entering the pressure reducing valve and affecting its performance. 2. It is necessary to flush the pipeline system before installing the vacuum valve. To prevent welding slag, oxide scale and other dirt from flowing into the valve, affecting the normal operation of the valve, 3. There should be a straight pipe before and after the pressure reducing valve of the device. The length of the straight pipe before the valve is about 600 mm, and the length of the straight pipe behind the valve is about 600 mm. 1000mm, the vacuum valve should be installed in a place convenient for operation and repair.

Since its transformation in 2000, Beipiao Vacuum Equipment Co., Ltd. has injected new vitality and vitality into the enterprise. It has successively developed large-caliber and special-shaped electric and pneumatic high-vacuum flapper valves. It has also developed rapid development for national defense and scientific research departments. Closed high-temperature water-cooled large flapper valve has become a domestic manufacturer of oversized valves.

Where to buy valves

The valve medium type changes, especially when the medium accumulation state is different (for example, from liquid phase to gas phase), the opening pressure often changes. When the working temperature rises, the opening pressure generally decreases, so adjust it at room temperature. At high temperatures, the set pressure value at room temperature should be slightly higher than the required opening pressure value. How high it is is related to the valve structure and material selection. It should be based on the manufacturer's instructions. The vacuum valve stainless steel joint material is generally 1Cr18Ni9Ti or 0Cr18Ni9, its hardness is close to the valve body.

The accuracy of the function of the vacuum valve is high, and the effective adjustment of the airflow direction and size of the vacuum environment is the standard that its function needs to meet. The vacuum ball valve, as a ball valve product used under vacuum conditions, not only cuts off The basic function positioning of the vacuum valve has standard accuracy, and while realizing the effective cut-off function guarantee, it can also serve the needs of vacuum environment management. It is necessary to ensure that there is a good management function. Vacuum valve products Practical application.

The products and services of Beipiao Vacuum Equipment Co., Ltd. are spread all over the country and have been well received by users. Our tenet is: "Customer needs are the goal we are constantly pursuing." Honesty, dedication, pioneering, and innovation are the company's spirit. We will provide high-tech products and various forms of services for domestic and foreign users. We look forward to sincere cooperation with colleagues from all walks of life. , Go hand in hand, create brilliant together!