Which companies have high vacuum flapper valves

The parts of the vacuum valve of the high vacuum valve are processed before assembly. According to the processing requirements, some parts need to be polished, and the surface must not have processing burrs, etc.; all parts are subjected to degreasing treatment; after degreasing is completed, pickling passivation is performed. The cleaning agent does not contain phosphorus; after the vacuum valve is pickled and passivated, it is rinsed with pure water, and there should be no residues. This step is omitted for carbon steel parts; each part should be wiped dry with non-woven cloth, and the vacuum valve should not be lined. Wait for the surface of the remaining parts, or blow dry with clean nitrogen.

Poor R&D capabilities for valves: It can be said that there is no or only a small amount of capital investment, even if it is the so-called new product development, it is just a mode of taking orders, designing, and producing, which to some extent causes unreliable equipment performance And the immaturity of the process has brought hidden dangers to the customer’s use. Foreign counterparts have invested a lot of money in research and development, researched and developed key parts and basic parts, and explored and solidified the process to form a product or a certain product. Field advantage.

Beipiao Vacuum Equipment Co., Ltd. (formerly Beipiao Vacuum Valve Factory) was established in 1966 and is a designated enterprise of the former Ministry of Machinery and Electronics. The total area of the factory is over 50 acres, the main factory is located in the Taiji Management Zone of Beipiao City, and the new factory is located in the Light Textile Industrial Park of the Economic Development Zone of Beipiao City, with a total investment of over 100 million yuan. There are 62 employees, including 12 engineers and technicians. The company has more than 100 sets of various processing and manufacturing equipment and nearly 20 patented technologies. Over the years, it has been innovating and making progress. It has grown into a professional vacuum acquisition, A high-tech enterprise of vacuum application technology development and equipment manufacturing.

After the valve heats the valve body of the vacuum valve, try to open slowly or open it fully and tightly and then close it slightly; loosen the packing gland and try to open; appropriately increase the valve stem gap; replace the valve stem and nut; readjust the packing gland Bolt; Straighten the door rod or replace it; the vacuum valve door rod uses pure graphite powder as the lubricant. Before the vacuum valve is rotated to adjust the screw, the valve inlet pressure should be reduced to below 0, 9 of the opening pressure to prevent the rotation of the adjustment screw When the valve disc is driven to rotate, resulting in damage to the sealing surface.

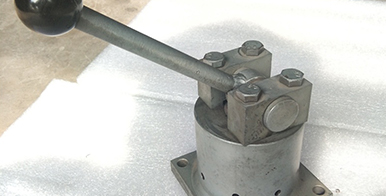

When injecting grease on high vacuum flapper valves, pay attention to the problem of the vacuum valve switch position. Similar to the vacuum ball valve, it is generally in the open position during maintenance. Under special circumstances, it is selected to be closed for maintenance. Other valves cannot be treated as open position. Also observe the problem of the vacuum valve diameter being flush with the sealing ring seat, such as vacuum ball valve, if there is an open position interference, you can adjust the opening limiter inward, confirm that the diameter is straight, and adjust the limit. The pursuit of opening or closing a position requires overall consideration.

The company is located in Beipiao City, Liaoning Province, in the west of Liaoning Province, with the Bohai Sea in the south and Inner Mongolia in the north. It is an important part of the Bohai Rim Economic Circle. Beipiao City is rich in fossil resources and mineral resources. 44 types of mineral resources have been proven. Among them, gold mineral reserves are very rich, and the fossil industry is prosperous and diverse. It is known as "the world's first bird flying and the first flower blooming." The reputation of "place".

Which companies have high vacuum flapper valves

If the valve is classified according to the working pressure of the actual starting system, it can have a rough vacuum system, a low vacuum system, a high vacuum system, an ultra-high vacuum system and a very high vacuum system. If it is divided according to the cleanness of the vacuum system, there will be an oil vacuum system. , Oil-free vacuum system, due to people’s habits, the above-mentioned different classifications are often integrated in practical applications, such as "large dynamic metal high vacuum system", "oil-free ultra-high vacuum system", etc. Therefore, the above classification The method is not strictly constant.

Before using the above method of screwing out the vacuum valve broken bolt, some conventional measures should be taken, such as kerosene soaking, cleaning the surface oil stains and rust (this is especially important for the screwing method of spot welding, otherwise the welding is not strong). , It can also heat around the bolts of the vacuum valve, unscrew the bolts under thermoplastic conditions, and use chemical corrosion methods to unscrew the broken bolts, and properly clean the rusty and corroded bolts and screw holes, which will accelerate Unscrew the broken bolts (after unscrewing the bolts, flush the screw holes with water to prevent the remaining chemicals from corroding the valve parts).

The transportation in Beipiao City is very convenient. The Beijing-Shenzhen high-speed railway can directly connect to Beijing, Shenyang and other cities. National highways 101 and 305 and Changshen Expressway run through urban and rural areas. The central city is 45 kilometers away from Chaoyang Airport and 150 kilometers away from Jinzhou Port.