High vacuum valve hotline

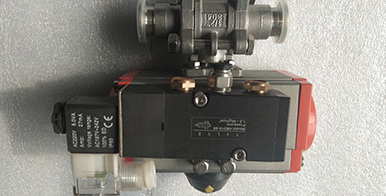

The driving mode of the high vacuum baffle valve is hand, air, electromagnetic, and electric. The GDC-J electromagnetic high vacuum baffle valve is sealed by a metal bellows, which has a wide range of applications and can also be used as an inflatable valve; installation The position can be arbitrarily, it can be reversed to one atmosphere, and there is a feedback signal output. The plug-in valve is used in the occasions with high vacuum requirements or high pipeline size requirements. It is fully conductive and the valve leakage rate is 10-7Pa, L/S, two-way The sealing, driving mode is determined by the user by hand, pneumatic and electric.

High vacuum valve vacuum valve packing gland should not be over-tightened. It is advisable that the valve stem can rotate sensitively. Pressing too tightly will increase the frictional force of the valve stem and increase the operating torque. Generally speaking, it cannot be used during valve operation. Replace or add packing under pressure at will, otherwise, it will cause the risk of medium leakage. The electromagnetic vacuum belt inflation valve and electromagnetic vacuum pressure difference valve are vacuum valves specially used to prevent the mechanical vacuum pump from returning oil. They are installed at the air inlet of the mechanical vacuum pump. It is turned on and off synchronously with the pump.

Beipiao Vacuum Equipment Co., Ltd. has a technical team with rich practical experience and specializing in the research and development of vacuum equipment. Over the years, through the continuous exploration and innovation of several generations of Beipiao people, the company can design and manufacture high vacuum oil diffusion pumps. , Oil diffusion jet vacuum pumps, various series of vacuum valves and vacuum units, etc., including more than 20 series of vacuum application equipment, more than 100 varieties of products.

High vacuum valve Electromagnetic vacuum belt charging valve and electromagnetic vacuum differential pressure valve are vacuum valves specially used to prevent oil from returning to mechanical vacuum pumps. They are installed at the inlet of mechanical vacuum pumps and open and close synchronously with the pump. Generally, they cannot be used elsewhere , Which means that it cannot be used for deflation in a vacuum system. The advantage of choosing Nivel electromagnetic vacuum differential pressure valve is that it consumes very little power and saves energy; the valve body with DN≤50 is made of aluminum alloy, which is light in weight. Small size, fast closing speed of valve plate.

The vacuum part of the high vacuum valve vacuum valve is mainly composed of the middle sandwich of the inner valve body and the outer valve body. The more gas in the sandwich, the more intense the convective heat transfer. In order to reduce the influence of convective heat transfer, the sandwich should be vacuumed. The heat transfer of the residual gas belongs to the migration of gas. For the gas heat conduction of the vacuum interlayer, with the strength of the interlayer, the heat conduction mechanism of the vacuum valve gas is different. The sealing structure of the inlet and outlet ends of the vacuum valve and the pressure test joint is a commonly used cone. The surface is in contact with the spherical surface.

Since its transformation in 2000, Beipiao Vacuum Equipment Co., Ltd. has injected new vitality and vitality into the enterprise. It has successively developed large-caliber and special-shaped electric and pneumatic high-vacuum flapper valves. It has also developed rapid development for national defense and scientific research departments. Closed high-temperature water-cooled large flapper valve has become a domestic manufacturer of oversized valves.

High vacuum valve hotline

Vacuum valve vacuum valve packing gland should not be over-tightened. It is advisable that the valve stem can rotate sensitively. If it is pressed too tightly, it will increase the friction of the valve stem and increase the operating torque. When the valve is operated, it should not be arbitrarily under normal circumstances. Replace or add packing under pressure, otherwise, it will cause the risk of medium leakage. When the diameter of the vacuum valve is different from that of the process pipeline, a reducer should be used for connection. When installing a small-diameter control valve, it can be connected by thread, and the flow direction of the valve body Should be consistent with the fluid direction.

The design of the high vacuum flapper valve vacuum system should ensure stable and reliable exhaust, easy installation, disassembly and maintenance, convenient operation, and interchangeability of connections between components. In order to achieve stable exhaust during work, stable performance of the main pump is required, and each valve Flexible operation and reliable sealing. The joints of the components in the system do not leak air. The vacuum chamber has good sealing performance. The vacuum components are connected in standard sizes to ensure interchangeability. In the vacuum system design, in principle, each closed tube The road size should have an adjustable size.

The products and services of Beipiao Vacuum Equipment Co., Ltd. are spread all over the country and have been well received by users. Our tenet is: "Customer needs are the goal we are constantly pursuing." Honesty, dedication, pioneering, and innovation are the company's spirit. We will provide high-tech products and various forms of services for domestic and foreign users. We look forward to sincere cooperation with colleagues from all walks of life. , Go hand in hand, create brilliant together!