What are the valves

Precautions for the use of high vacuum valves Vacuum valves 1. When storing and transporting vacuum valves, the pressure on the sealing parts will decrease, which will cause the loosening of screws and nuts. In order to avoid the resulting leakage, vacuum valves are used Be sure to tighten each screw beforehand. 2. When the vacuum valve uses high-temperature fluids such as steam, the tightened screws will become loose due to the reduced pressure on the sealing parts, resulting in leakage. Therefore, the loose screws should be tightened immediately.

After the high vacuum flapper valve is assembled, the welding seam of the vacuum valve cannot be exposed to the outside. China's vacuum equipment industry has made great development and significant improvement since its opening for more than 20 years. This is not only reflected in the substantial increase in output value and output, Moreover, considerable achievements have been made in terms of types, specifications and comprehensive technical levels. China's vacuum equipment industry has made great development and substantial improvement since its opening for more than 20 years. This is not only reflected in the substantial output value and output. Increased, and achieved considerable achievements in terms of types, specifications, and comprehensive technical levels.

Beipiao Vacuum Equipment Co., Ltd. specializes in the research and development, design and production of vacuum valves, vacuum chambers, molecular pumps and molecular pump units with a highly skilled team, and continues to develop new products. Products are widely used in aerospace, technology, coating, solar energy, vacuum furnace industry, energy, metallurgy, chemical industry and many other industries.

Principles and precautions for valve vacuum valve pressure test (1) Under normal circumstances, the valve is not subjected to strength test, but after repairing the valve body and bonnet or the valve body and bonnet damaged by corrosion, the strength test should be conducted. For the valve, its constant pressure And the return pressure and other tests should meet the requirements of the instructions and related regulations. (2) The strength and tightness test of the valve installation should be carried out, the low-pressure valve should be randomly checked 20%, and the vacuum valve should be checked if it is unqualified; medium and high pressure The valve should be checked.

The design of the high-vacuum valve vacuum system should ensure stable and reliable exhaust, easy installation, disassembly and maintenance, convenient operation, and interchangeability of connections between components. In order to achieve stable exhaust during work, stable performance of the main pump and flexible operation of each valve are required. , The sealing is reliable, the joints of the components in the system do not leak air, the vacuum chamber has good sealing performance, and the vacuum component connection adopts standard dimensions to ensure interchangeability. In the vacuum system design, in principle, the size of each closed pipeline There should be an adjustable size.

The main service groups of Beipiao Vacuum Equipment Co., Ltd.: colleges and universities; research institutes; customers with high vacuum and ultra-high vacuum requirements. The company takes scientific development, forge ahead, the pursuit of excellence, and casting fine products as the development concept. "Customer first, service first" is the business policy.

What are the valves

The power standard of the valve vacuum valve is very clear, and among the possibilities of realizing the application of automatic functions, in the real situation with good quality assurance, what needs to be considered is the adaptability of the valve function itself and the application. To achieve practical goals on the basis of production, the quality requirements are strict, the vacuum valve force is lower than the atmospheric pressure, and the pressure drop on the valve disc cannot exceed 1 kgf/cm2. The working temperature of the medium depends on the process of using the device.

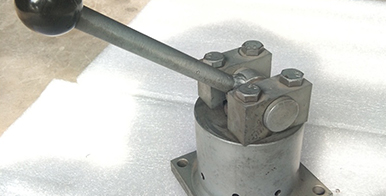

Vacuum valve vacuum flange connection or flange joint refers to a foldable connection that is connected by flanges, gaskets and bolts as a set of combined sealing structure. Pipeline flange refers to the flange used for piping in the pipeline installation. Used on the equipment refers to the inlet and outlet flanges of the equipment, which are reliable, can be opened in any direction, are easy to disassemble, and are easy to clean. The vacuum flange uses copper gaskets and flange knife edges to realize the vacuum sealing function, and the vacuum flange is sealed. There are various types, fixed and rotatable, and bolt holes are divided into so-called threaded holes and through holes.

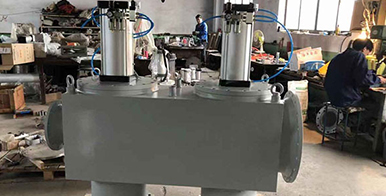

The main products of Beipiao Vacuum Equipment Co., Ltd. vacuum valves include: ultra-high vacuum flapper valve, high vacuum butterfly valve, high vacuum baffle valve, ultra-high vacuum all-metal angle valve, ultra-high vacuum all-metal fine-tuning valve, etc. The valve diameter ranges from 10mm to 1200mm, the applicable temperature range is -80℃~~+400℃, and the applicable pressure range is 105~~10-8pa.

The main products of the vacuum chamber are: arc structure, round structure, square structure, various vacuum pipes can be processed and manufactured according to the drawings, and the cavity size ranges from 0.1 to 16m.