1 Overview

This article uses Solidworks software to qualitatively and quantitatively analyze the selection method of each parameter in the design of triple-eccentric butterfly valve.

The selection of the eccentricity parameters and cone angle of the triple eccentric butterfly valve determines whether the valve interferes when it is opened, whether the sealing surface pressure is uniform when it is closed, and its sealing reliability.

2. Structural analysis

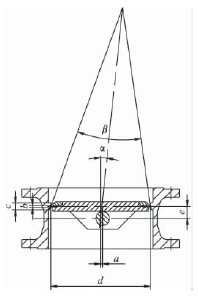

The entire closing process of the triple eccentric butterfly valve (Figure 1) will not cause interference. At the moment of final closing, the entire sealing surfaces are attached to each other, similar to the closing characteristics of a globe valve. Therefore, the triple eccentric butterfly valve is a torque-sealed valve, which breaks the limitation that the butterfly valve can only be used as a position-sealed valve in the past.

The triple eccentric butterfly valve's 7 parameters including radial eccentricity a, dynamic seal pair thickness b, static seal pair thickness c, sealing surface ellipse major axis d, axial eccentricity e, eccentric angle α and cone apex angle β can determine the triple eccentric butterfly valve. The sealed sub structure. d is determined by the nominal diameter DN of the valve, e is determined by the thickness of the valve disc and the diameter of the valve shaft, b and c are determined by the design pressure of the valve, the sealing surface material, and the sealing surface specific pressure, a, The choice of α and β determines whether the triple eccentric butterfly valve is closed or not, which involves whether the specific pressure of the sealing surface after closing is uniform and whether the seal is reliable.

Figure 1 Triple eccentric butterfly valve

3. Interference analysis

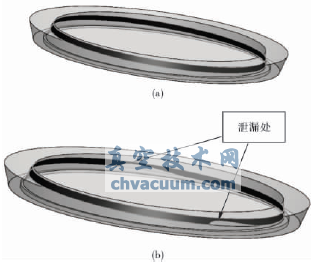

No matter how the parameters are selected, the sealing pair of the butterfly plate and the valve body is completely fit when the valve is fully closed. If there is no interference when opening the valve, the sealing pair of the passing valve will definitely interfere (Figure 2a). If there is interference when the valve is opened, the sealing pair of the passing valve will partially interfere and partially disengage (Figure 2b). The parameter selection at this time is not available.

(A) The seal pair of the clearance valve fully interferes

(B) Partial interference of the seal of the pass valve

Figure 2 Working state of valve seal

Only when the situation in Figure 2a occurs, the selected parameters are available. However, a valve will have countless parameter combinations that can meet the situation in Figure 2a. Only by selecting the optimal parameter combination can the sealing performance of the valve be guaranteed and the difficulty of valve manufacturing can be reduced.

4. Data analysis

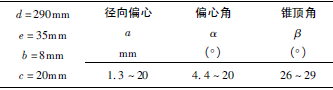

Take the DN300 ultra-low temperature butterfly valve as an example to analyze the method of selecting each parameter. The DN300 ultra-low temperature butterfly valve is designed to be used in the air separation industry, and it needs to work for a long time under the cryogenic condition of -196℃. In this design, d is 290mm, e is 35mm, b is 8mm, and c is 20mm. The value range of a, α, and β can be determined by Solidworks software (Table 1).

Table 1 Value range of parameters a, α, β

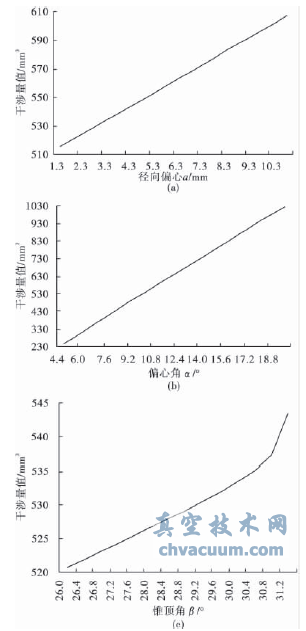

Within the value range of parameter a, α, β, a single change of a parameter passes the valve by 0.3°, and the interference amount of the seal pair is calculated. Take the transformation parameter as the abscissa and the interference quantity as the ordinate to draw a graph of the change trend of the parameters and the interference quantity (Figure 3).

(a) Radial eccentricity (b) Eccentricity angle (c) Cone apex angle

Figure 3 Relationship between parameters and interference

From the relationship between radial eccentricity, eccentric angle, cone apex angle and interference amount, it can be seen that within the non-interference parameter range, radial eccentricity, eccentric angle and cone apex angle have a positive linear relationship with the interference amount.

5 Conclusion

The effects of the various parameters of the triple eccentric butterfly valve on valve sealing and interference are interrelated. There are countless parameter combinations that can meet the design requirements under the same design requirements. However, it is necessary to comprehensively consider various factors such as the opening and closing torque of the valve, the reverse pressure bearing capacity, and the manufacturing difficulty. Through Solidworks interference calculation, we can understand the influence trend of each parameter change on the valve performance change, and then choose the best parameter combination.